The customer approached us and requested that we tighten the machine for their printer assembly project.The assembly process requires 3 different screw specifications,2 different torque requirements,and 112 screws.

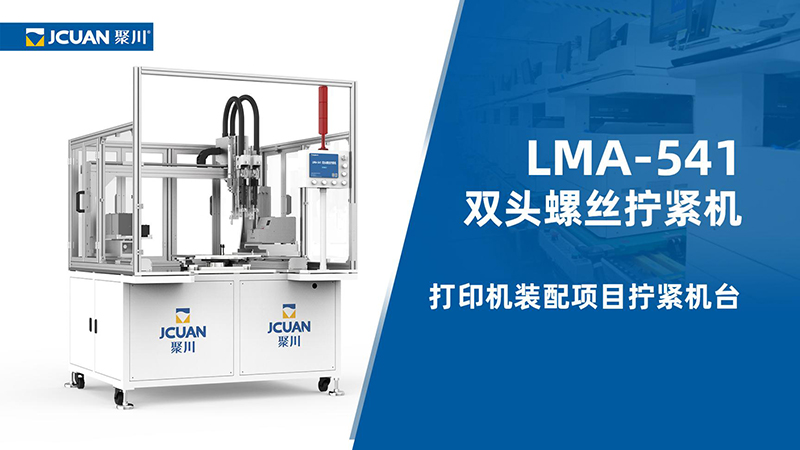

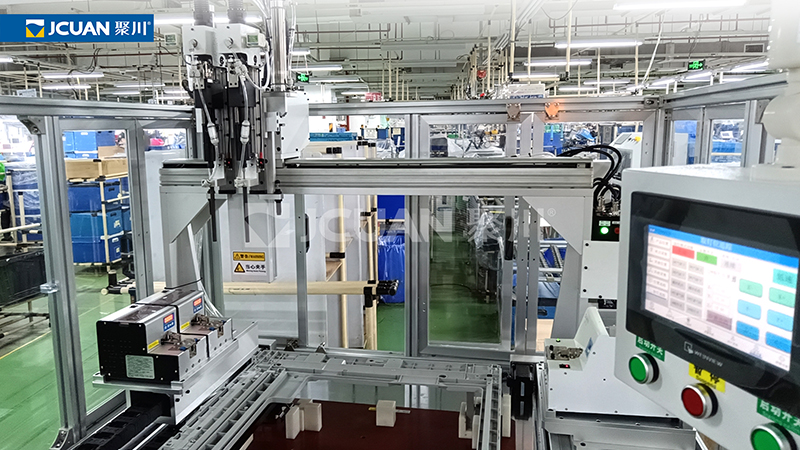

We have tailored a printer assembly project tightening machine for our customers in a short period of time.The LMA-541 double headed screw tightening machine adopts a floor standing frame structure and is designed with screws on both sides to meet the alternating tightening of three specifications of screws.The overall length of the machine is 1465mm,the width is 1300mm,and the height is 2050mm.The working range can meet the length,width,and height requirements of 750*650*300mm.It is composed of X-axis module mechanism,Z-axis module mechanism,Y-axis module mechanism,3 nail supply mechanisms,2 sets of tightening mechanisms,servo motors,and electrical control devices to achieve the project objectives.

The machine has a sliding tooth alarm detection function;

●Floating lock detection function,with a floating lock detection accuracy of±0.5mm;

The standard tightening cycle of the equipment is about 2-3 seconds,and there may be slight differences in the spacing between the holes;

The system adopts a PLC+touch screen structure,with stable performance and the ability to store multiple sets of tightening processes;

The fixture can rotate freely,be positioned and fixed,and perform multi-faceted operations;

Among them,the core components of the machine are the independently developed brushless mechanical tightening shaft and automatic machine specific screw supply device by Juchuan.

The brushless mechanical tightening shaft is designed based on flexible tightening technology,with a torque range of 3-15kgf.cm and can be freely adjusted;The speed is 700-1000,with two adjustable gears;And equipped with torque protection mechanism;Support the replacement of different products with different batches of nozzles and suction nozzles.

Equipped with three specialized screw feeders for automatic models,two types of screw feeders are SEM-30B for large material storage and SEM-30S for small material storage;

SEM-30B is suitable for various specifications of screws with a diameter of M2.0-8.0 and a length less than 30mm.It can be used for single fixed-point feeding,which is convenient for machine material retrieval and stable without jamming!

SEM-30S is suitable for M1.0-5.0 screws,and special screws can also be used.The screw feeding point is stable,the feeding accuracy is high,and the performance is stable!

Dongguan Juchuan's customized printer assembly project tightens the machine for customers,with stable performance,high efficiency,high precision,low noise,and no material jamming!And with a one-year warranty,you don't have to worry about after-sales issues at all!We specialize in providing industrial screw tightening technology and automation application solutions,as well as professional tightening equipment.Please choose Dongguan Juchuan!