Function Introduction

Electronic setting of arbitrary values

Electronic setting,torque,angle,and speed can be set to any value

Multiple parameter settings

Multiple screws can support parameter settings for different torques,angles,and speeds

Meet different process requirements

●Supports torque+angle mode,enabling multiple process operations for a single screw

Tighten data traceability query

●Automatic data storage,real-time generation of data table files,and downloadable and transferable

Tightening status monitoring display

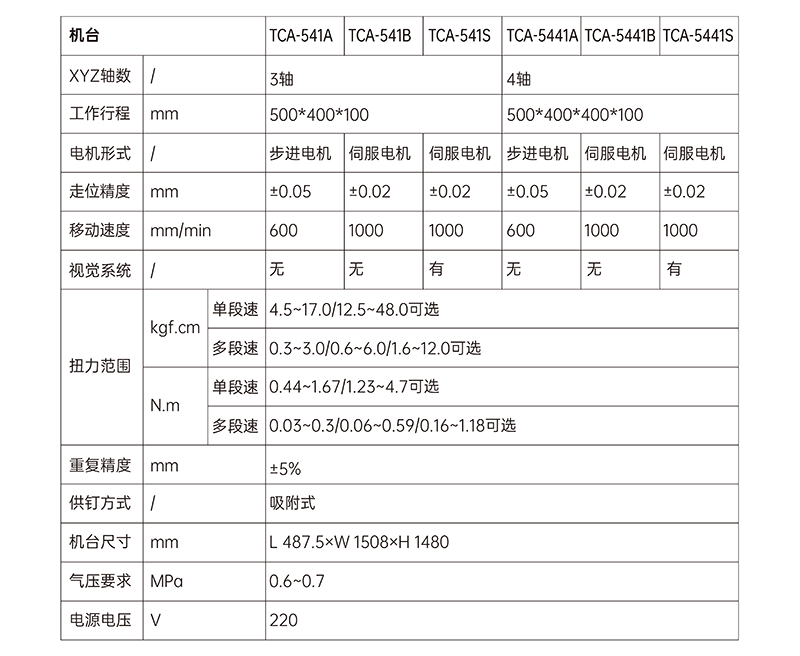

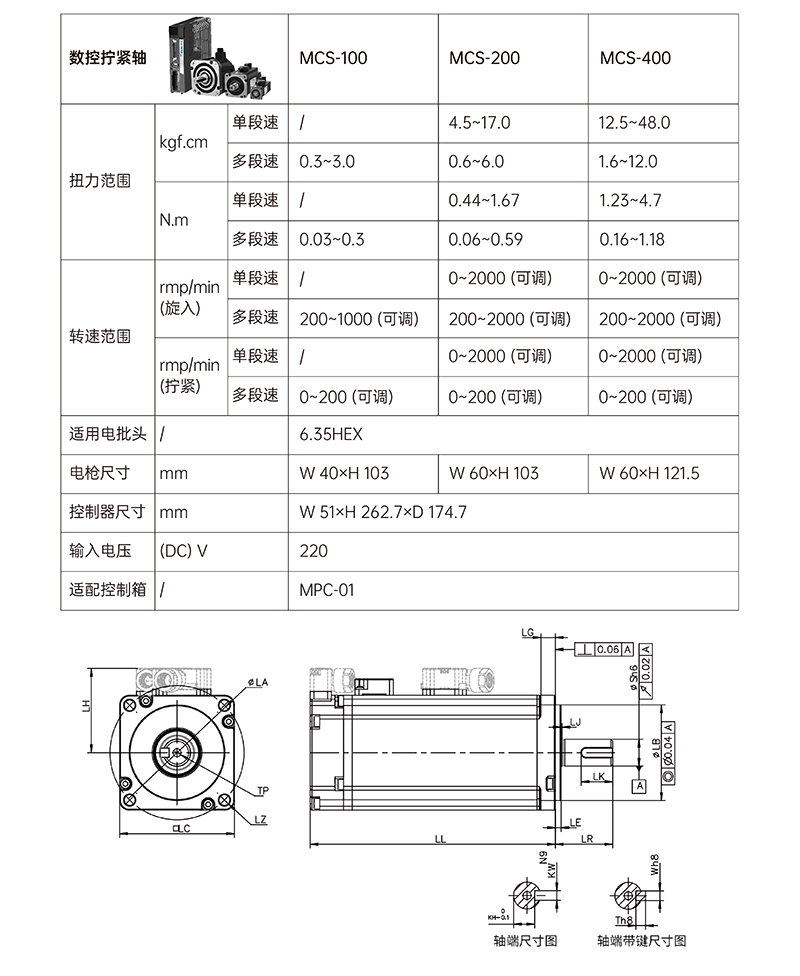

Specification parameters

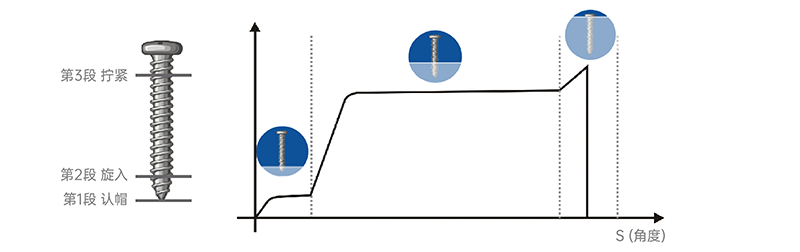

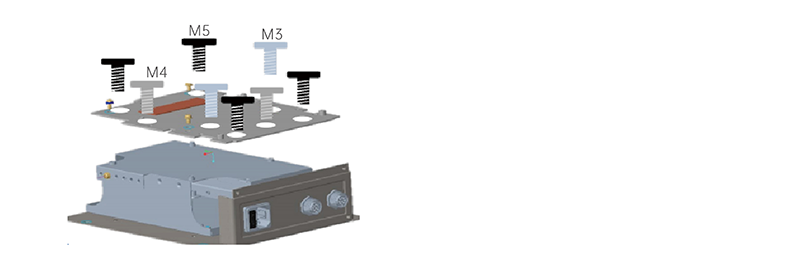

01 Torque+Angle Mode

① 认帽阶段-该阶段工具低速运行,螺丝与牙孔是否顺利契合;

② 旋入阶段-该阶段工具高速运行,直到达到降速条件,整个过程扭矩回授较低,无明显变化;

③ 拧紧阶段-以该阶段工具低速运行,设定目标扭矩或目标角度,完成锁付任务。

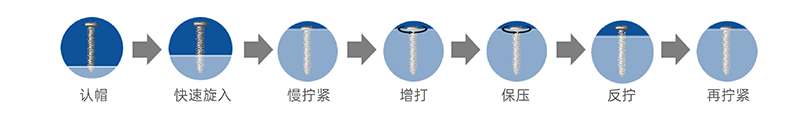

02 Tightening process

● A single screw can achieve multiple tightening processes,and its torque,angle,and speed can all be electronically set.

●

Multiple screws can perform different torque,speed,and angle values,and their tightening status and data can be effectively traced.

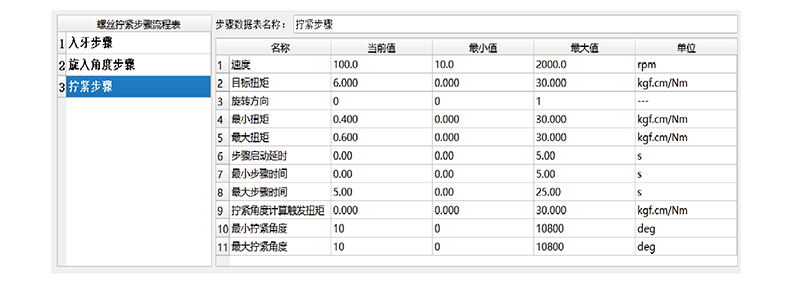

03 Electronic Setting of Parameters for Various Projects

● Various screw tightening steps can be systematically set: tooth insertion step, screw in angle step, and tightening step.

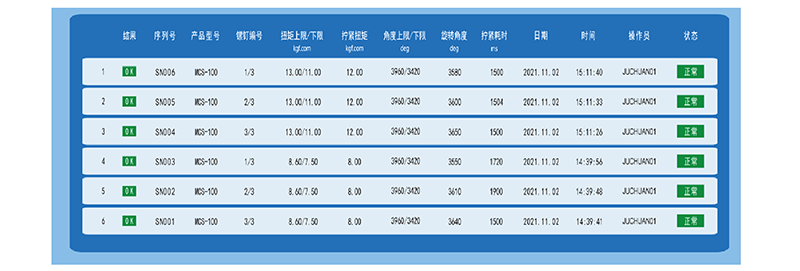

04 Multi directional real-time monitoring data - traceable

Real time display of tightening process data;

Multi directional data monitoring,with traceable tightening results,product serial numbers,current status,and other data;

●Automatic data storage,real-time generation of data table files;

Can be connected to MES system for data exchange.