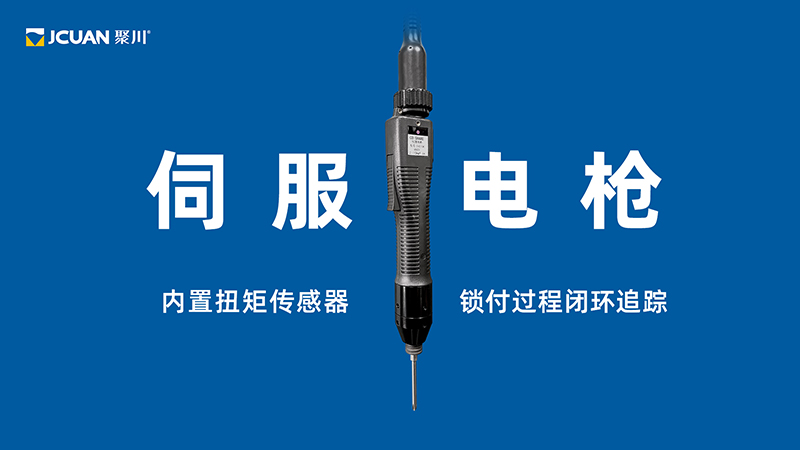

Dongguan Juchuan servo electric gun, with built-in torque sensor, can meet the tightening needs of various processes within 12N.M. It supports code scanning and MES communication, and its tightening data is traceable!

Servo stun guns are used when demanding torque, precision, and multi-data tracking are crucial. They quickly complete complex tightening or disassembly tasks while ensuring the precise force applied to each screw. They are commonly used in applications such as new energy batteries, energy storage, charging stations, inverters, automotive manufacturing and maintenance, 5G communications, military, and aerospace, ensuring precise tightening.

This is the Dongguan Juchuan D-series servo stun gun. It includes a servo stun gun and a servo controller, which can be connected to a computer and a barcode scanner. Optional accessories include a 90° elbow and a vertical bracket.

➢ The servo stun gun is available in multiple sizes, with a torque range of 1 kgf/cm (minimum) to 85 kgf/cm (maximum).

➢ The ergonomically designed handle reduces hand fatigue, enhancing comfort and ease of use!

➢ The built-in torque sensor offers high accuracy, fast frequency response, excellent reliability, and long life, enabling closed-loop tracking of the tightening process!

Before using the Juchuan D series servo electric screwdriver, first log in to the external computer and set the "counter setting" and "torque point setting" related parameters. This is the key to ensure tightening accuracy!

Multiple Counter Settings:Set process parameters

●Group Settings:Up to five counter groups can be set,with each group containing up to 10 counters,and each counter containing up to 99 screws.

●Process Parameter Settings:Different counters can be configured to correspond to different process parameters.

For example,different process requirements,different screws,and three different torques and speeds.

We can set multiple groups and multiple counters to meet the tightening needs of a wide variety of products.

Torque Point Settings:Set relevant tightening parameters,including speed,torque,and angle.

●Speed:Set any speed within the specification.

●Torque:Set any torque within the specification,with a tolerance range.An alarm will be issued if the tightening result exceeds the preset value.

●Angle:The target angle is the angle required to reach the target torque after the starting torque.Exceeding the preset value will trigger an alarm.This can be used for floating lock detection.

For example,if a screw needs to be tightened at multiple speeds,

We can set the number of idle revolutions and speed,the number of forward revolutions and speed,and the trigger torque based on the screw specifications to ensure every screw is tightened properly,improving product quality and assembly efficiency!

Visualize and trace data throughout the entire process,ensuring control over the tightening process of each screw,traceable tightening results,and accurate and reliable tightening data!Quickly detect tightening failures such as loose locks,slipped threads,missed or mis-drilled screws,and missing gaskets!

1.The servo gun has indicator lights that illuminate according to the tightening results:"Pass"illuminates green,"Slipped"illuminates red,and"Floating Lock"illuminates yellow.

2.The controller screen displays relevant data for the current tightening operation:tightening status,target torque,actual torque,tightening angle,tightening results,and count display.

●Tightening results:Pass,Pass-Major Cycle Completed,Pass-Minor Cycle Completed.

●Tightening results:Slipped,Floating Lock,Low Torque,etc.

3.Monitoring can be enabled on the PC.Once enabled,the results of each tightening operation are displayed,along with the progress of the counter,consistent with the controller display.Torque-time and angle-time curves can also be displayed.

The PC supports querying all recorded process data:date,time,gun ID,group number,counter number,screw number,target torque,tightening torque,tightening angle,time taken,tightening status,etc.

●Automatically generates files to a specified location for easy access.

●Connects to an MES system for data exchange.

●Supports QR code scanning.

Juchuan's D-series servo electric screwdrivers offer superior quality,stable performance,durability,and a long screwdriver life,saving maintenance costs.They help you achieve true automation,digitization,and intelligence,reducing costs and increasing efficiency.We specialize in industrial screw tightening technology and automation application solutions.Contact us for more details!