Function Introduction

Process mode

● Supports torque + Angle mode, enabling multiple process operations for a single screw

Display monitoring

● The system displays the current operating parameters and can effectively monitor the tightening status of the current screws

Editable

● Electronic setting, torque, rotation Angle and rotational speed can be set to any value

Data traceability

● 数据自动存储,实时生成数据表格文件,且可下载及传输

Real-time monitoring and display

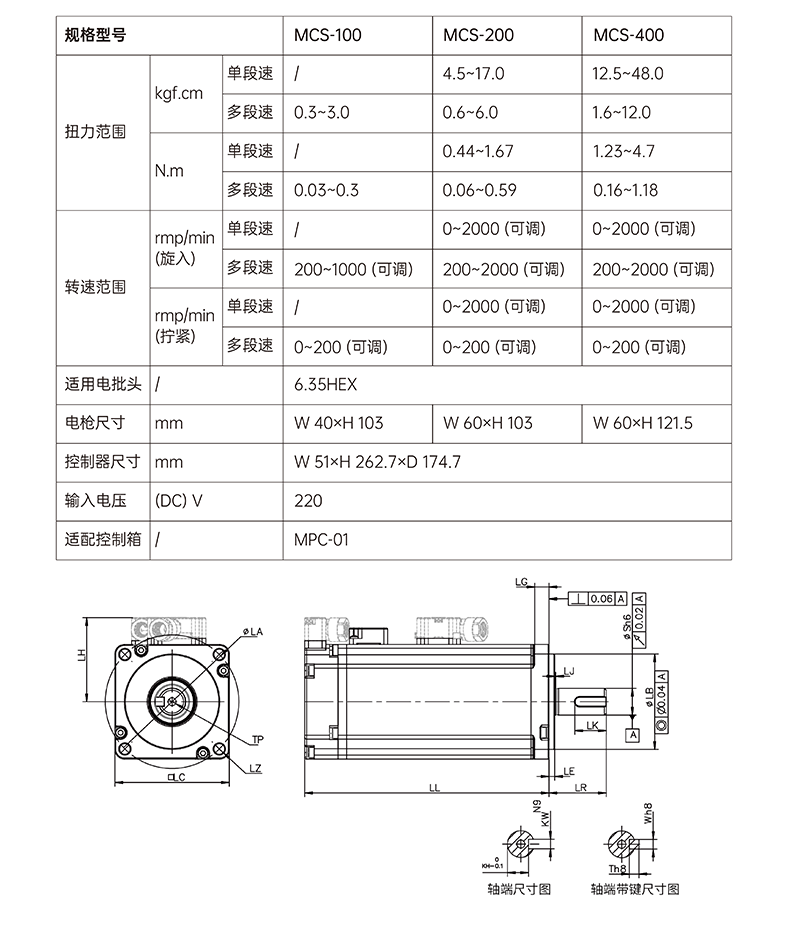

Specification parameters

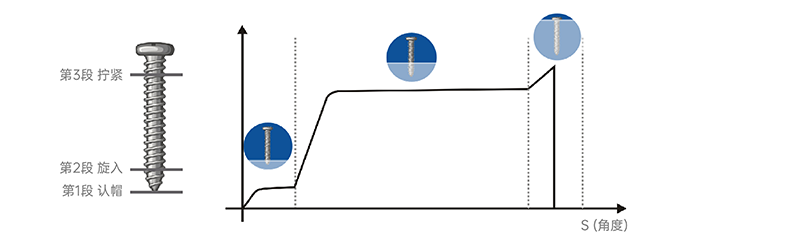

01 Torque + Angle mode

① Cap recognition stage - During this stage, the tool runs at a low speed to check if the screw fits smoothly with the thread hole.

② Screw-in stage - During this stage, the tool operates at high speed until the deceleration condition is reached. Throughout the process, the torque feedback is relatively low with no significant change.

③ Tightening stage - Run the tool at a low speed during this stage, set the target torque or target Angle, and achieve the locking target.

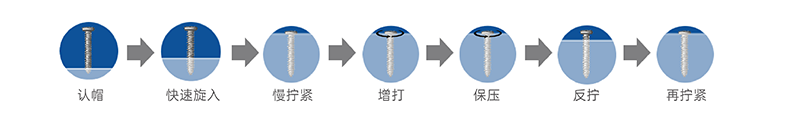

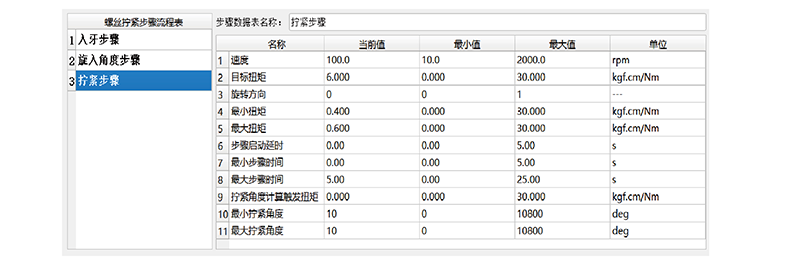

02 Tightening process

● A single screw can achieve multiple tightening processes, and its torque, rotation Angle and rotational speed can all be set electronically.

● A variety of screws can perform different torque, rotational speed and Angle values, and their tightening status and data can all be effectively traced.

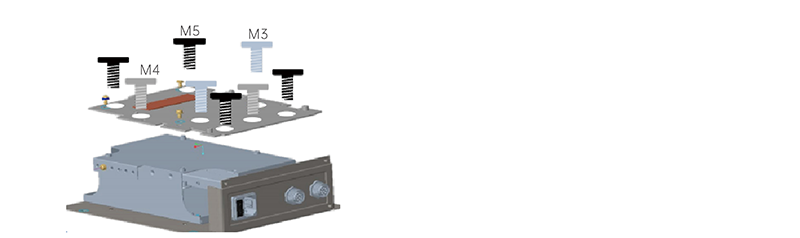

03 Electronic setting of parameters for each project

● Electronic setting of parameters for each project

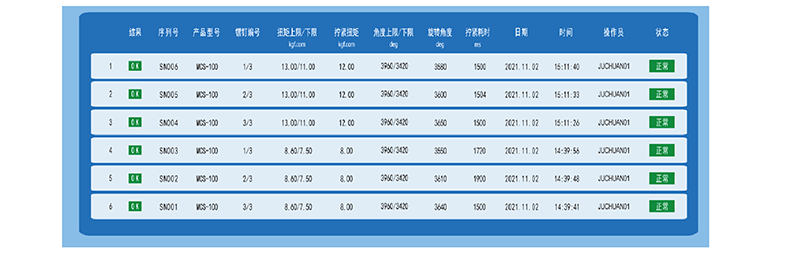

04 Multi-directional real-time monitoring data - traceable

● Real-time display of tightening process data;

● Multi-faceted data monitoring, with traceable data such as tightening results, product serial numbers, and current status.

● Data is automatically stored and data table files are generated in real time.

● It can be connected to the MES system for data interaction.