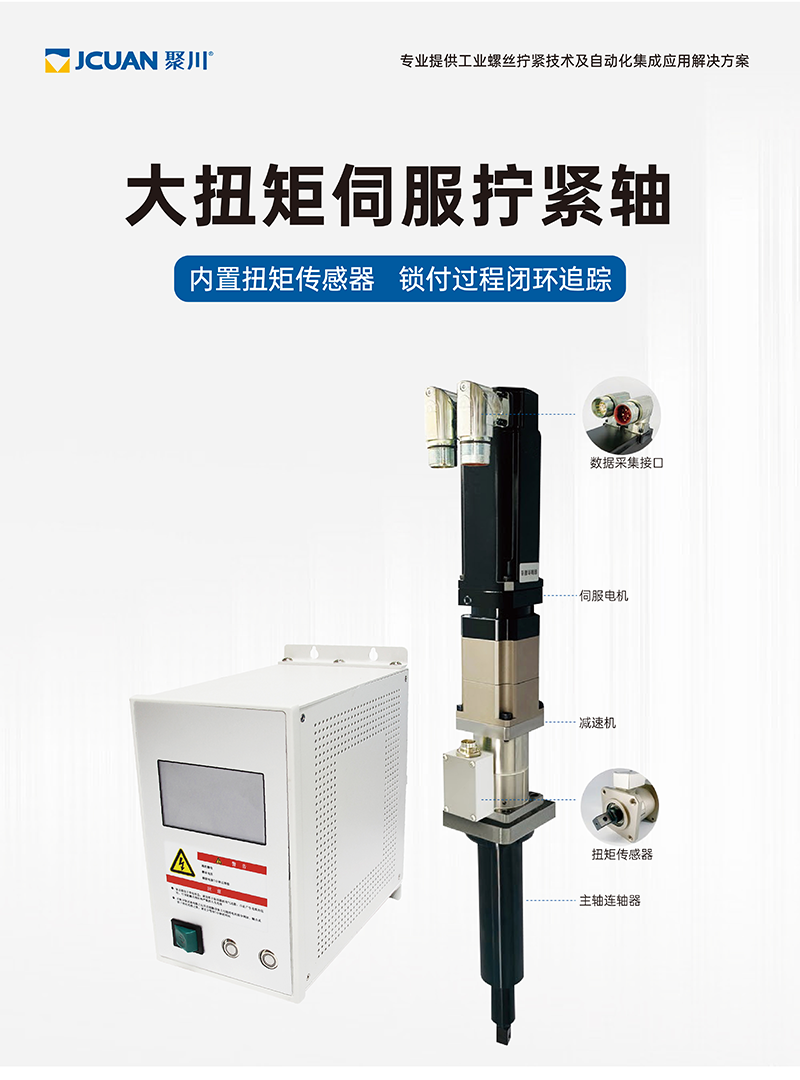

Function Introduction

The tightening process is controlled by high-speed digital technology

● Errors such as torque, rotational speed, rotation Angle, screening slippage, and false lock

Rich input/output control signals

● Start, stop, forward and reverse rotation, tightening completed, whether qualified, error alarm, etc

Real-time display of key data

● Torque value, Angle, process time, whether qualified or not, etc

Stable data collector

● Real-time data collection and storage are carried out, with stable and large capacity (customized collectors can be provided as needed to output data externally).

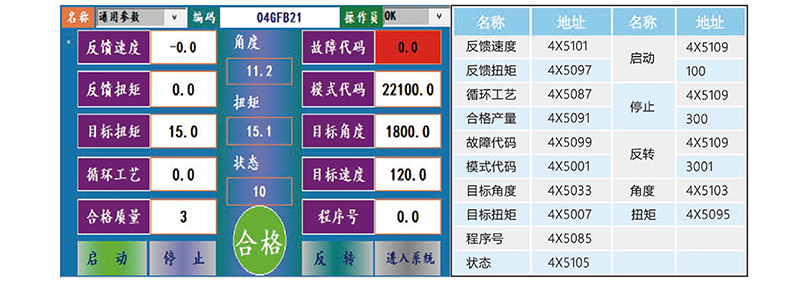

Real-time monitoring and display

Main parameter display and status feedback

Main parameter display and status feedback

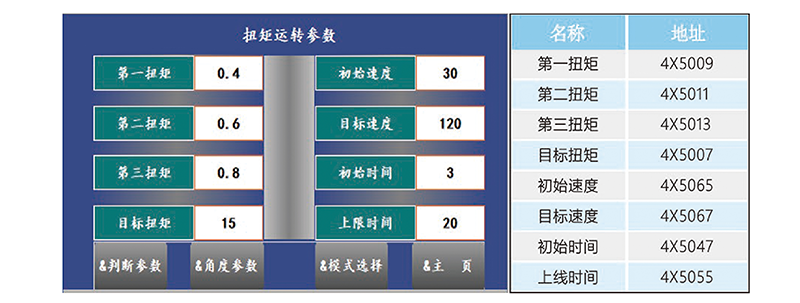

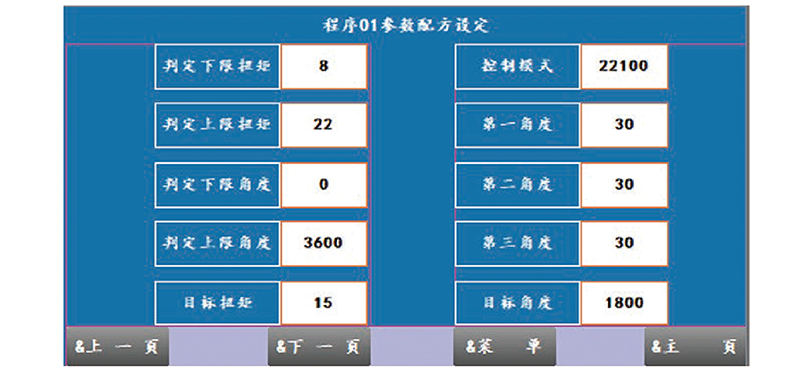

01 Tightening parameter setting

● Torque: Within the specification, the torque values of sequence one, two, and three can be set, and the target torque, initial speed, target speed, initial time, upper limit time, etc. can also be set simultaneously.

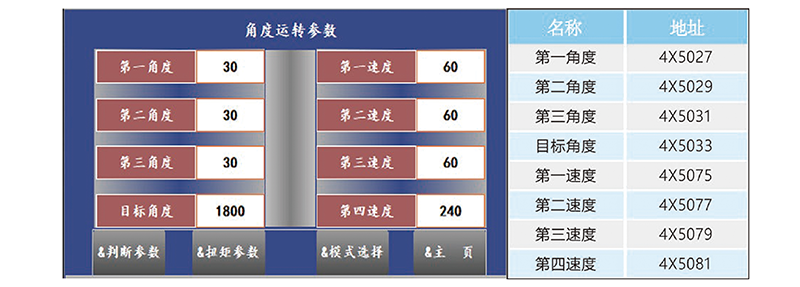

● Angle: Within the specification, sequence one, two, and three Angle values can be set, and the target Angle and the speed parameter when executing the corresponding Angle can also be set simultaneously.

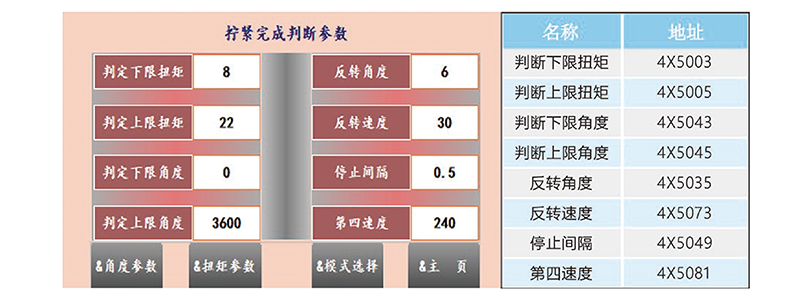

● Tightening completion judgment: Set the qualified parameters for tightening completion: upper/lower limit torque, upper/lower limit Angle, reverse Angle, reverse speed, and stop interval time, and monitor in real time whether the tightening completion is qualified.

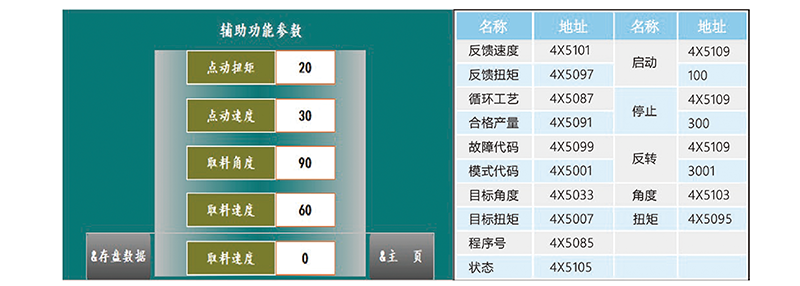

● Other auxiliary functions: For automatic assembly, other auxiliary parameters can be set: point torque, point speed, material picking Angle, material picking speed, cycle process, etc.

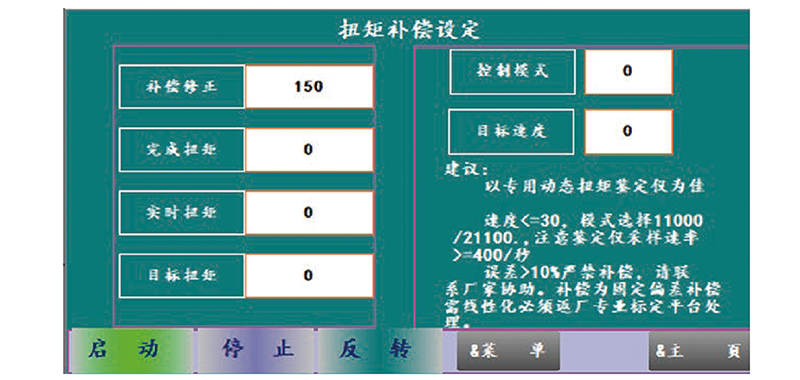

02 Mode setting, program number setting, axis calibration correction

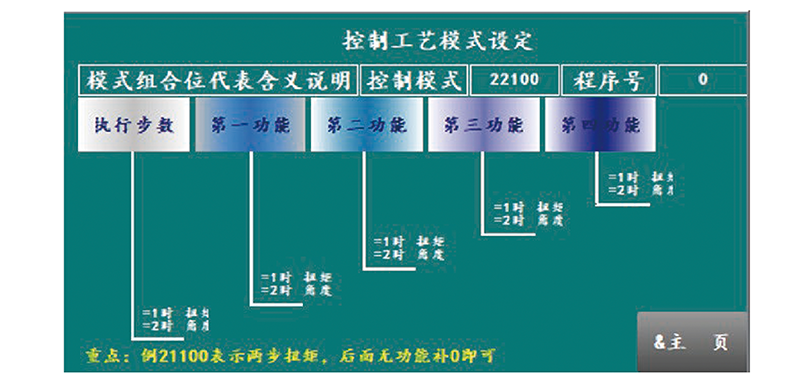

● Mode: Different process parameters can be set under the process mode to meet the tightening requirements of various types of products.

● Program Number: 1 to 20 program numbers can be set, and different parameter formulas can be set according to the job requirements. All formula parameters are stored on the display screen. When the program number is received, the specified parameters will be transmitted to the controller for operation.

● Shaft calibration and correction: After the shaft has been in use for a certain period of time (half a year/year), parameters can be set for torque compensation Settings. It is best to calibrate it with a dedicated dynamic torque calibrator.

03 Data records are traceable

● Data traceability: After each successful tightening, the data acquisition software collects and stores data in real time, and data files can be exported within a set time range. Data collectors can be customized as needed, and data is output externally through the ETHERNET port.