Multi group point control

It can feed materials in 1-15 different quantities,with accurate counting.

Rotary type material sorting

●Rotary discharge,with accurate discharge position each time and a repeat positioning accuracy of±0.1,can better coordinate with robotic arm operations.

LCD display counting

●Through the digital display panel,different parameters can be set,which is easy to adjust and intuitive.

Smooth operation

●The screws run inside the drum,and any screws that do not enter the track in the normal direction will fall into the drum and enter the next cycle without any jamming.

Adjustable feeding efficiency

●The parameters such as the speed and vibration size of the feeding turntable can be adjusted directly on the display screen,making the operation simple.

Anti strong light interference

●Function upgrade,not affected by strong light interference,can still work normally under strong light.

Shortage alarm function

●When there is a shortage of material in the silo and it exceeds the time limit,the feeder will automatically sound an alarm.

overload protection

●Newly upgraded control motherboard,in case of material jamming,the system automatically controls the motor to reverse for a certain period of time,effectively protecting the motor and circuit board.

Customizable options

● Customizable screw length detection function, detecting screws with length exceeding the preset value and giving alarm prompts, effectively preventing mixing and misuse, and improving the quality of work.

● Customizable 485 communication function can be used to remotely control the screw machine, including controlling the number of points, starting and stopping supply, and data transmission.

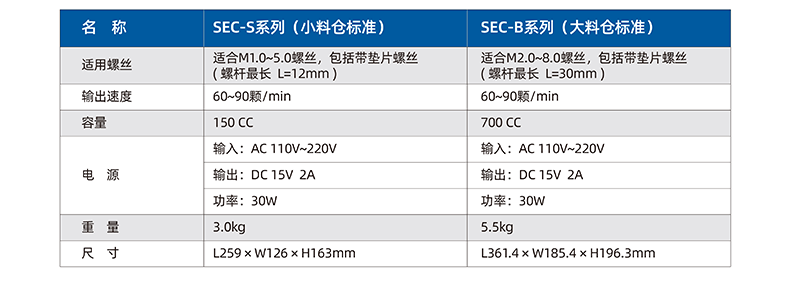

performance parameter