Order Number:JQ-212

Model JQ-212

Item No.JQ-212

Brand Juchuan

Type:DC ion fan

The direction of the airflow is straight ahead

Material:iron

Low-pressure fan

Low-noise performance fan

It is used for static electricity removal and dust removal

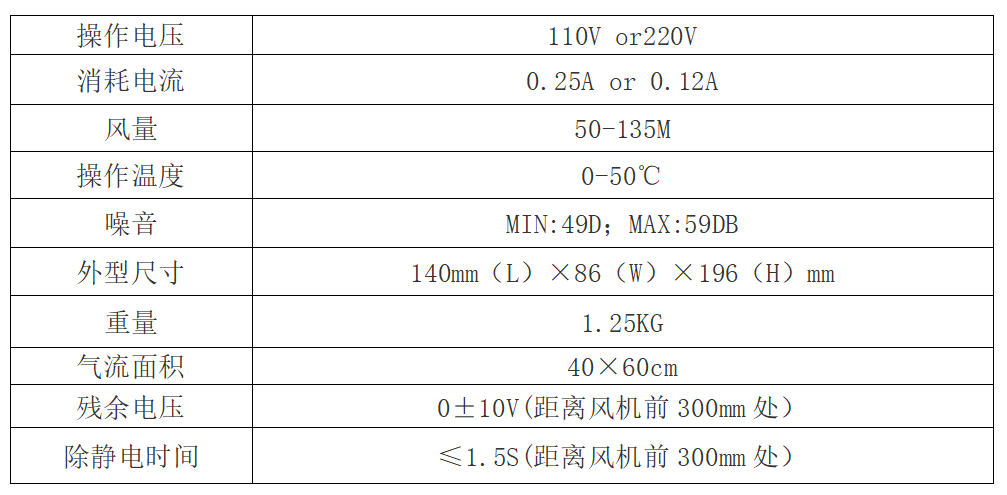

Ion air volume 50-135(cfm)

Power dissipation time:1(s)

Input voltage:220(V

Application scope:Electronic production lines,circuit board production lines,optoelectronics,printing,chemical industry,LED display,etc

Installation distance:30 cm

The effective range of the ion wind zone is 1000

Ion equilibrium degree 5

The external dimensions are 140mm(L)*86mm(W)*196m

Product features

1.Neutralize ionic static electricity rapidly

2.The ionic airflow has a large coverage area

3.The wind force adjustment range is wide

4.There is a dedicated ion emission cleaner

5.Automatic cleaning function

6.Ionization indicator

7.The fan has good grounding protection

8.Ion equilibrium voltage stability

Principle of operation

The Juchuan JQ-212 DC ion fan can generate a large amount of airflow with positive and negative charges, which can neutralize the charges carried by objects. When the surface of an object carries a negative charge, it will attract the positive charges in the airflow; when the surface of an object carries a positive charge, it will attract the negative charges in the airflow. Thus, the static electricity on the surface of the object is neutralized, achieving the purpose of eliminating static electricity.

Technical parameters

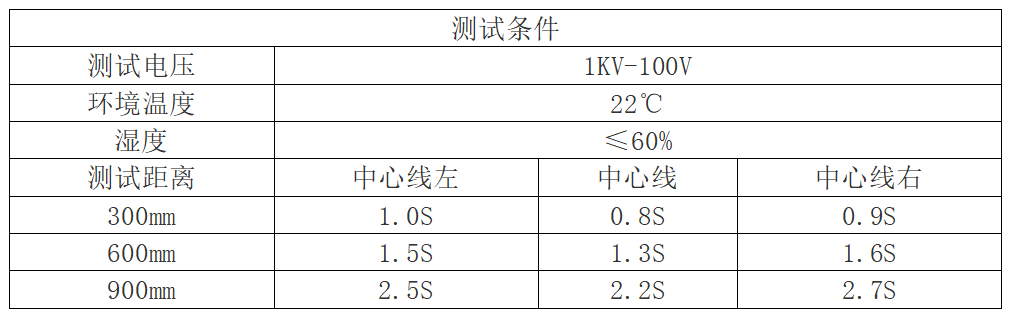

The result of the static electricity removal test

*The electrostatic elimination time complies with ESD standards and is measured from 1000V to 100V

*The test instrument used is the ME268A electrostatic comprehensive tester,and the test results are in accordance with the standard

*Test data may vary due to changes in the temperature of the surrounding air

Safety measures

1.Before installation and operation, the operation manual must be read

2.It must be reliably grounded before operation

3.No items are allowed to be inserted at the entrance and exit of the grating

4.The fan must not be operated in flammable and explosive environments

5.No unauthorized repair is allowed

Operating Instructions

1.This equipment has been debugged at the factory. Please do not adjust the ion balance without any evidence proving that the equipment parameters have changed

2.Remember never to use a conductor to pull people from the sensor (iron mesh cover) for an arc test. During operation, the sensor (iron mesh cover) must not touch any other objects either

3.Please do not test or verify the balance of the ion fan in a ground environment prone to static electricity (such as a blanket floor, etc.), as such a ground can cause the tester's body to carry high static electricity, thereby greatly affecting the accuracy of the test or verification

4.The power supply for this ion fan must have a good grounding terminal

5.Do not insert any foreign objects through the air inlet or outlet bars

6.Never use this equipment in flammable and explosive environments

7.Only the manufacturer is qualified to carry out internal repair or maintenance

Maintenance details

1.To prevent the accumulation of particles and loose soil from hindering the ion airflow or forming Bridges between the ion needle and the ground wire attachment, it is very important to remove static electricity and loose soil and residues in the fan chamber

2.A simple method is to regularly clean the fan chamber with high-speed compressed air. The compressed air can enter from the air inlet and outlet of the fan chamber.

(The rear mesh cover can also be removed with an ion air gun and cleaned with a brush. The ion needle can be replaced.)

3.The specific time for regular maintenance depends on the operating hours and the cleanliness of the environment where the ion fan is located